Metal Inert Gas (MIG) welding, also known as Gas Metal Arc Welding (GMAW), is one of the most widely used welding processes in industrial manufacturing, automotive repair, and DIY projects. At the core of this versatile welding method is the MIG welding torch, a crucial tool that delivers wire, electrical current, and shielding gas to create strong, clean welds.

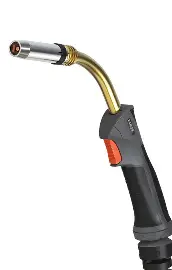

Components of a MIG Welding Torch

To understand how MIG welding torches function, it’s essential to familiarize yourself with their main components:

- Handle: The part the welder grips, often containing the trigger mechanism.

- Neck: Connects the handle to the contact tip and nozzle.

- Liner: A tube that guides the wire from the wire feeder to the contact tip.

- Contact Tip: A copper component that transfers electrical current to the wire and directs it to the weld pool.

- Gas Nozzle: Directs the flow of shielding gas around the weld area.

- Gas Diffuser: Helps distribute shielding gas evenly around the wire.

- Power Cable: Delivers electrical current from the power source to the torch.

- Gas Hose: Supplies shielding gas to the torch.

- Control Wires: For trigger function and sometimes wire feed speed control.