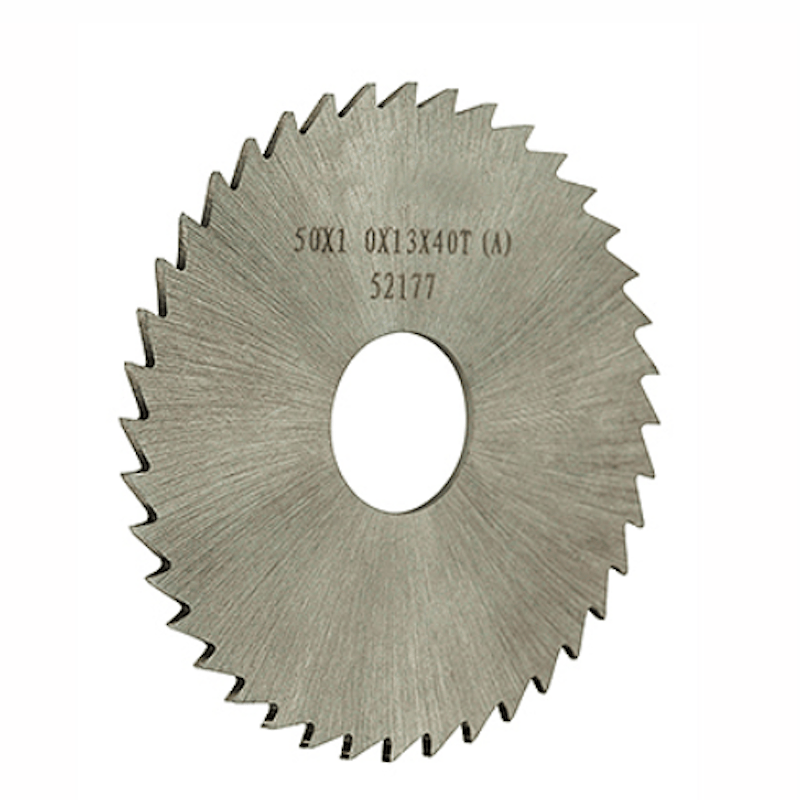

We the Fastlane Engineering and Hardware Limited are proud to be associated with the High Speed (steel) cutting Tools Industry for more than 4 decades. Our Company supplies products such as HSS Tool bits, Hand Hacksaws, Power saws, Metal cutting band saws, Bi Metal Bandsaws, HSS Taps, Endmills, Slot drills, Reamers, Annular cutters, Gear cutters, Slitting saws, Sided face cutters, Tungsten Carbide Rotary burrs, Solid carbide drills, Carbide brazed tools, low Alloy blades, Files and Grinding stones.

High-speed cutting tools are revolutionizing manufacturing by offering this very capability. This article explores the materials used in these tools—like diamond, boron nitride, and ceramics—and their specific applications.

High-Speed Cutting Tool: Materials and Versatile Applications

Imagine cutting metal with a precision so fine it saves time and reduces costs. High-speed cutting tools are revolutionizing manufacturing by offering this very capability. This article explores the materials used in these tools—like diamond, boron nitride, and ceramics—and their specific applications. By reading further, you’ll learn how these advanced materials enhance cutting efficiency and discover the best options for your machining needs.

Hard Alloy

Hard alloy, also known as cemented carbide, is a composite material manufactured through powder metallurgy techniques, combining hardening compounds of refractory metals with bonding metals, typically cobalt. This advanced material exhibits exceptional properties, including high hardness, wear resistance, and thermal stability, making it invaluable in various industrial applications.

The production process involves carefully blending carbide powders (usually tungsten carbide) with metallic binders, followed by compaction and sintering at high temperatures. This results in a unique microstructure that balances hardness and toughness, crucial for demanding cutting operations.