Carbide tool inserts are crucial components in modern machining and metalworking processes. They offer superior cutting performance, longevity, and versatility, making them indispensable in various industrial applications. In this comprehensive guide, we’ll delve into everything you need to know about carbide tool inserts, including their types, applications, material properties, and how to select the right one for your needs.

Overview of Carbide Tool Inserts

Carbide tool inserts are replaceable tips used in machining to cut, shape, and finish materials. They are made from carbide, a composite material consisting of tungsten carbide particles bound together with a metal, usually cobalt. This combination gives carbide inserts their renowned hardness and durability. They are used in turning, milling, and drilling operations across various industries, from automotive to aerospace.

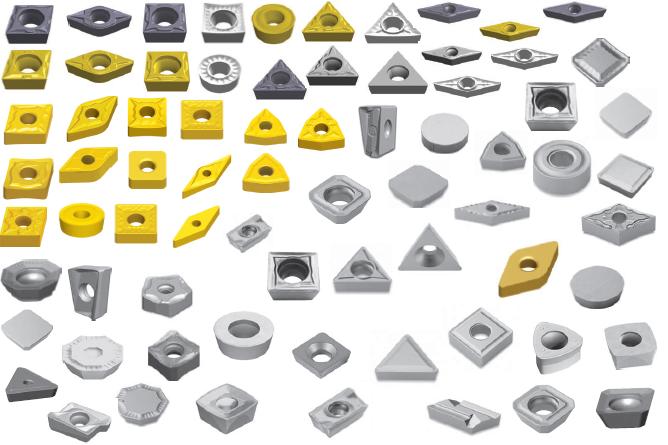

Types of Carbide Tool Inserts

Carbide tool inserts come in numerous shapes, sizes, and compositions, each suited for specific tasks and materials. Here’s a table to present the different types of carbide tool inserts:

| Insert Type | Shape | Typical Applications |

|---|---|---|

| CNMG | Diamond | General turning, facing, and finishing |

| TNMG | Triangle | Medium to heavy cutting, general purpose |

| SNMG | Square | Roughing, interrupted cuts, heavy-duty applications |

| VNMG | V-Shaped | Finishing, profiling, and high-precision applications |

| WNMG | Hexagon | Medium to heavy roughing and interrupted cuts |

| CCMT | Diamond | Light to medium cutting, high precision, and finishing |

| DCMT | Diamond | Finishing and light cutting |

| SCMT | Square | Medium to roughing, interrupted cuts, and heavy-duty applications |

| RCMT | Round | Light to medium turning, profiling, and high-speed cutting |

| APKT | Rectangular | Milling operations, high feed rates, and heavy-duty applications |

Applications of Carbide Tool Inserts

The versatility of carbide tool inserts makes them suitable for a wide range of applications. Here’s a table to present carbide tool insert applications:

| Industry | Application |

|---|---|

| Automotive | Engine components, transmission parts, suspension systems |

| Aerospace | Turbine blades, landing gear, structural components |

| Medical | Surgical instruments, implants, prosthetics |

| Oil & Gas | Drill bits, casing, downhole tools |

| Manufacturing | General machining, tool and die making, mold manufacturing |

| Electronics | Micro-machining, PCB manufacturing, semiconductor device |

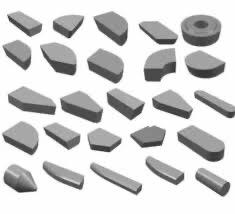

Carbide tips are made from a blend of carbide (typically tungsten carbide) and a binder material, often cobalt. The result is a highly durable material that is both hard and wear-resistant. Carbide tips are used in cutting tools for applications that involve high heat, pressure, and friction.