Angular milling or angle milling is a CNC milling operation that involves machining a surface at an angle with the angle milling cutter. Today, we’ll get into the basics of angle milling and the cutting tool, more importantly, there are different ways you can refer to for how to cut angles on a milling machine.

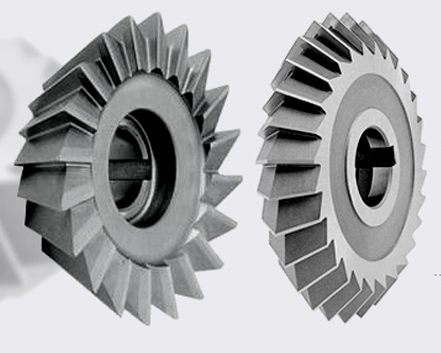

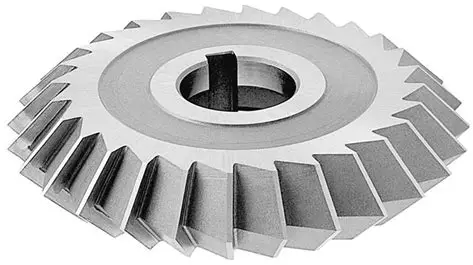

Angle milling cutters are specialized tools used to cut angled surfaces on a workpiece. There are two main types: single-angle cutters and double-angle cutters. These cutters are designed to cut one side of an angular surface at a time and are commonly used for making serrations, producing V-notches, and milling threads. The process of angle milling involves milling flat surfaces that are neither parallel nor perpendicular to the axis of the cutting tool.

Angle milling cutters come in either right hand and left hand variety.They are manufactured using high quality high speed steel to make the effective in whichever environments.They include 30°,45°,60°,65,°70°,75°,80 and 85°